In line with National Electric Mobility Mission and Thrust of Government of India on Electric Mobility, rapid growth in the Electric Mobility is evident in India.

As a part of the National Electric Mobility Mission Plan 2020 (NEMMP 2020), the Department of Heavy Industries, Government of India formulated a scheme namely Faster Adoption and Manufacturing of Hybrid & Electric vehicles in India [FAME-India], wherein it is intended to support the hybrid /electric vehicle market development and its manufacturing ecosystem to achieve self-sustenance at the end of the stipulated period. The scheme is one of the green initiatives of the Government of India, which will be one of the biggest contributors in reducing pollution from road transport sector in near future. The scheme has 4 focus areas i.e. Technology Development, Demand Creation, Pilot Projects and Charging Infrastructure.

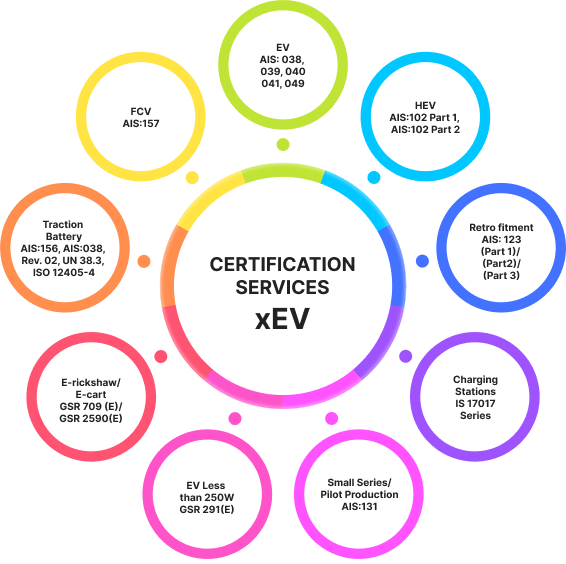

ARAI, premier research and certification institute in the country, has geared itself to support automotive industry for EV development, evaluation, and certification. Under the FAME project, ARAI has set up the comprehensive state of the art Centre of Excellence (CoE) for Electric Vehicles (2W, 3W, passenger cars, buses and commercial vehicles) and their components such as traction batteries, motors, controllers, chargers etc. This centre will support government’s electric mobility mission to scale up electric vehicles in India.

Our Expertise

Industries We Serve

Automotive

Automotive

Tractors & Farm Equipment

Tractors & Farm Equipment

Off-Road

Off-Road

Electric Vehicle

Electric Vehicle

Technology

Technology

Energy

Energy

Gensets

Gensets

Aerospace

Aerospace

Railways

Railways

Defence

Defence

Elevators

Elevators

Medical

Medical

Shipping

Shipping

Construction

Construction

AT THE HEART OF WHAT WE DO

Our Core Services

EV/HEV Services

E-Motor and Controller Characterization

- 220 kW, 150 kW, 30 kW Motor Test bed

Traction Battery and BMS

- Characterization of Li-Ion Cells, Module and Pack

- Battery Abuse Testing

- Electrochemical Impedance Spectroscopy / Analysis

- Battery & BMS Emulation

- BMS Testing

EV Charger

- EMC Electrical Safety and ENV Testing

- Protocol Validation (EVSE to EV and EVSE to CMS)

Electric / Hybrid Electric Vehicle Testing

- Performance on Chassis Dynamometer

- Vehicle Safety Testing (Electric Shock / IP / Water Effect Testing)

EMC Testing

- CAE Simulation for Chassis Design and Battery Pack Material Characterization for Lithium-Ion Battery

E-Powertrain Services

Hardware in Loop

- Multi disciplinary Plant model

- Real time simulation for Inverter, MCU, VCU

E-Powertrain Validation

- Net Power, Continuous Power and efficiency; Reliability, durability and overload capacity.

- Dynamic behaviour and dynamic measurements.

- Testing of regenerative braking, Thermal Characteristics

Vehicle in Loop

- E-powertrain Components in MiL/HiL setup for accelerated development.

- Development/validation of VCU software with real and emulated components.

- Integration of EV components in lab and simulation of real-world conditions

Vehicle EMC Facility

| Sr | Title | Details |

|---|---|---|

| 1 | Chamber Dimensions | 26m x 18m x 9m |

| 2 | Vehicle Entry Gate | 4m x 4m |

| 3 | Dyno Axle Control | 2 active axles, for vehicles with rear / front or four-wheel drive |

| 4 | Turn-Table Diameter | 9 m |

| 5 | Dynamometer Axle Load | 12,000 kg per axle |

| 6 | Radiated Immunity | 150 V/m from 100kHz to 6 GHz |

| 7 | Radiated Emission | EMI Receiver along with suitable antennas for the frequency range 9 kHz to 18 GHz |

| 8 | Provisions for EV/HEV testing | Grid compatibility testing like Harmonics, flicker, EFT, Surge, Power fail simulation, etc. Suitable high voltage AC/DC RF filters for integration of battery simulator, AC/DC chargers, etc. |

Certification & Compliance

| Sr | Services | Vehicles / Devices |

|---|---|---|

| 1 | CMVR Type Approval | All types of 2 & 3 wheelers |

| 2 | EMC control plans & Guidelines | All types of Passenger Cars |

| 3 | Pre-compliance & Compliance Testing | HCVs up to 9m length |

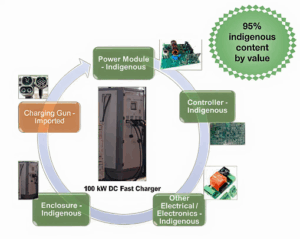

EV Charging Infrastructure Services

- EV charger Technology know-how transfer

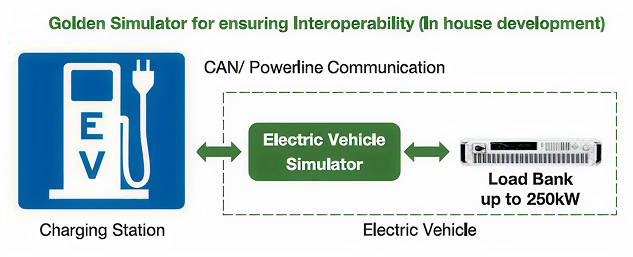

- EV and EVSE Simulation for Interoperability

- Development of Charger Control Unit for EV

- Charger testing and Validation

- Grid compatibility testing

- OCPP Back End Simulation