Drivetrain Development Centre

Drivetrain Development Centre (DDC)– Your development partner

With the changing mobility trends and evolving customer demands for electric vehicles and other mobility segments, Drivetrain Development Centre (DDC) supporting industry with advanced test facilities and expertise to address development needs for Performance, Durability, Benchmarking and NVH assessment for Conventional as well as EV applications. Facility can support to accelerates vehicle level platform development through DVP plan execution along with advanced HIL, MIL assessment capabilities under one roof for Passenger cars, Light & Heavy commercial Vehicles, Tractors and Earth Movers etc.

Electric Vehicle Drivetrain

- Flexible layout to adapt EV– Powertrain, E-axle, E–motor development testing.

-

Performance mapping and Range estimation:

- Different voltages, Ambient temperatures, Lubricant and Coolant parameters

- Different driving cycles: WLTC, JC08, MIDC etc

- Validation in Drive, Coast, Derating and Regeneration modes

- Vehicle Road Load Simulation (RLS)

- Calibration support for E–motor, Inverter and E–axle system

- Established platform for HCV, BUS High torque motor development

Hardware in Loop Simulation

- Validation of vehicle components safety and functionality checks with respect to software updates before vehicle proto development

- Connectors & harness verification, component integration over CAN and LIN protocols

- Battery charging and discharge cycles with real driving conditions simulating on powertrain.

- AC and DC charging validation with the support of charging infrastructure

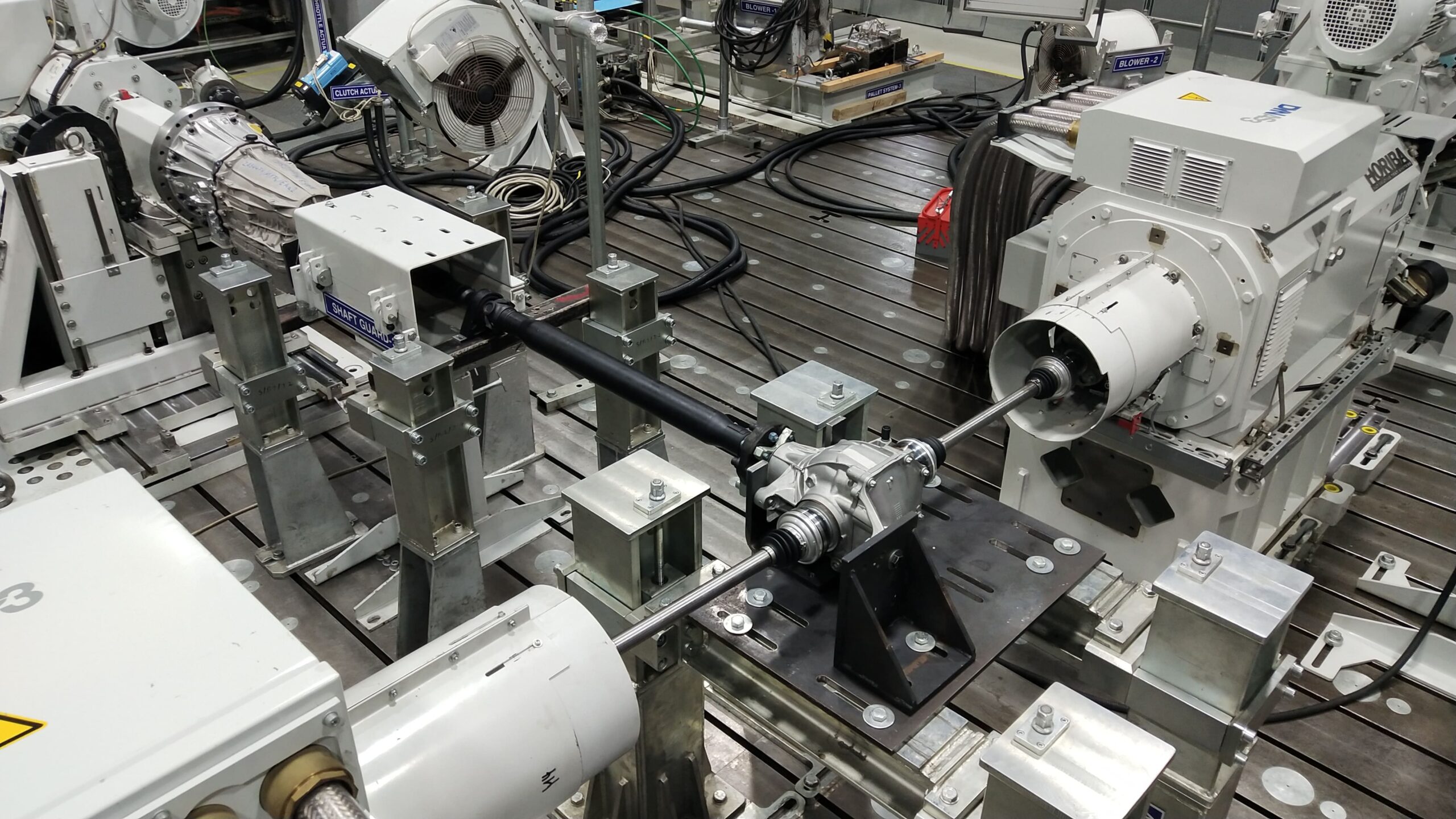

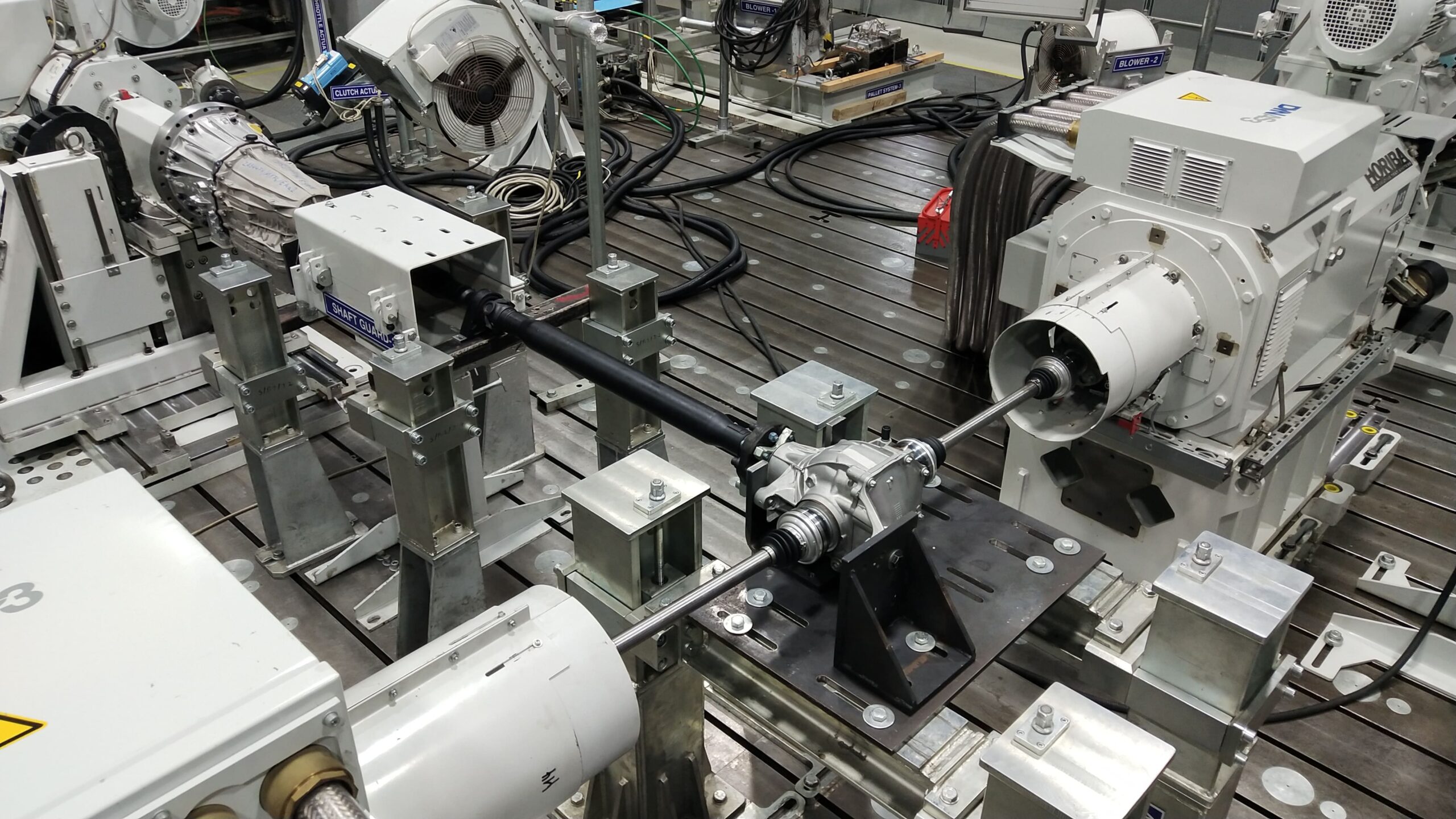

Complete Driveline and Subsystems

- Calibration of FWD/ RWD/ AWD Drivetrains – Motor–Inverter–Transaxle / Axle

- Various CAN Interfaces for communication with ECU, MCU, TCU.

- Digital I/O signals for control units to simulate vehicle conditions.

- Efficiency and Power loss measurements wrt lubricants Grade, Temperature and Quantity.

- Accelerated Durability Testing & Driving Cycle Simulation: WLTC, JE05, MIDC etc.

- Explicit testing of driveline for functional and design validation: EV, Hybrid, Conventional and Automatic (DCT, CVT, AMT)

EV– Transaxles, Manual & Automatic Transmissions, Axles, Differentials & Transfer Case

- DVP execution for accelerate development: Lubrication and Breather performance, Dynamic seal test, Efficiency, Accelerated durability, Differential Seizure, cornering, High-temp & High-speed test, NVH assessment etc

- Efficiency and Power loss measurements wrt lubricant Grades, Temperature and Quantity, as per SAE J-2453, 1540, 1266 standards.

- Provision to apply torque difference to simulate vehicle level torque distribution in case of 4WD/AWD applications for Transfer-case.

- Differential performance: Delta Speed & Delta Torque simulation, Transient fatigue testing of differentials: LSD, Open and locked differentials.

- Temperature Stability and durability of lubricants

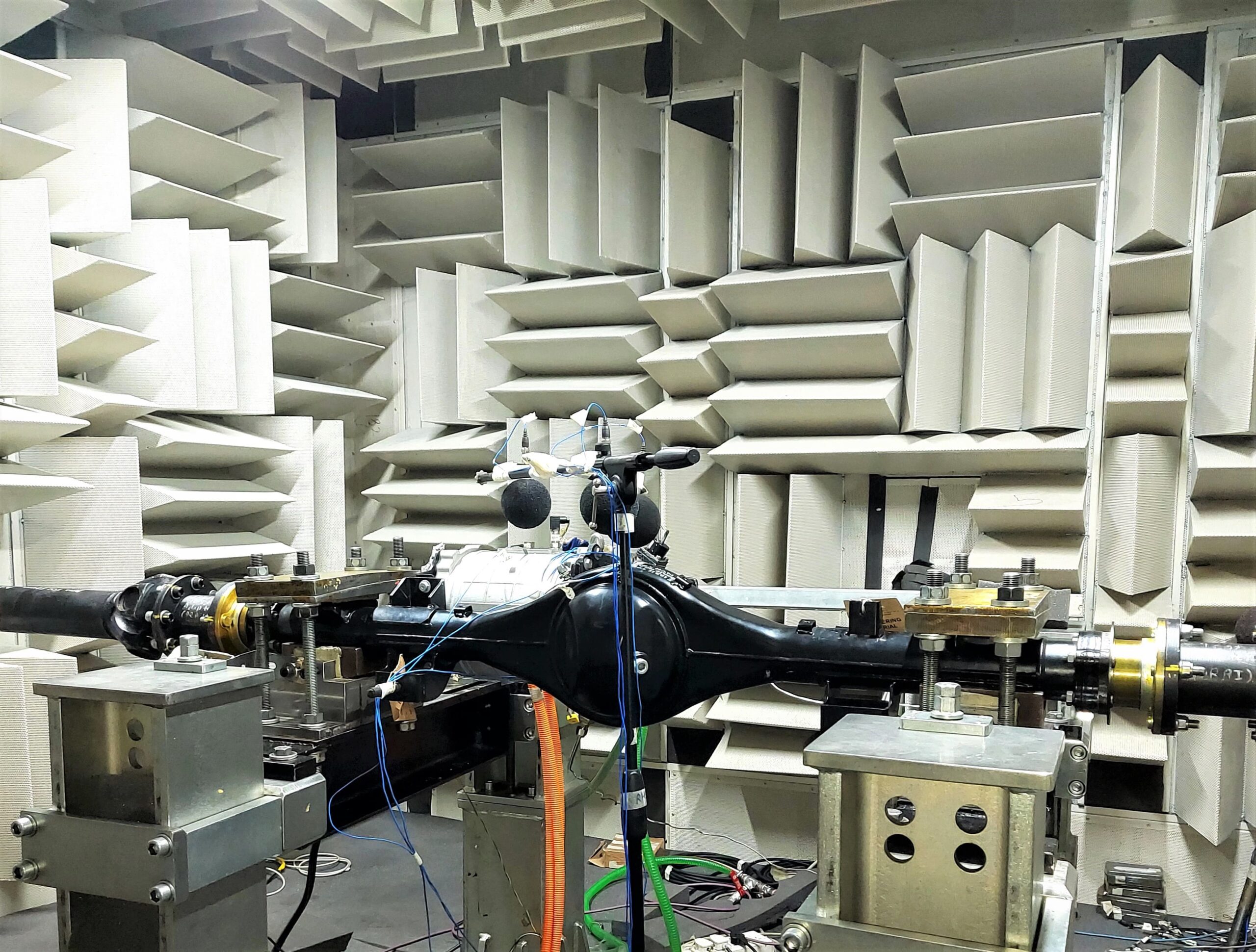

EV– Transaxles, Manual & Automatic Transmissions, NVH Assessment of Driveline components

- Modular anechoic chamber to accommodate wide range of EV–Driveline and sub-component NVH assessment.

- Noise source identification: SPL, SWL, Linear and Torsional vibration measurement.

- End-to-End solution for whine noise reduction

EV– Transaxles, Manual & Automatic Transmissions, Other Mobility Solution

- Specialized testing for Defense, Aerospace, Off-road, Railway, Metro, construction vehicle and Agriculture driveline and sub-components.

- Accelerated durability and Performance evaluation of tracked vehicle - Transfer case, Fluid coupling retarder, Intermediate Gear box to support for indigenous development.