About us

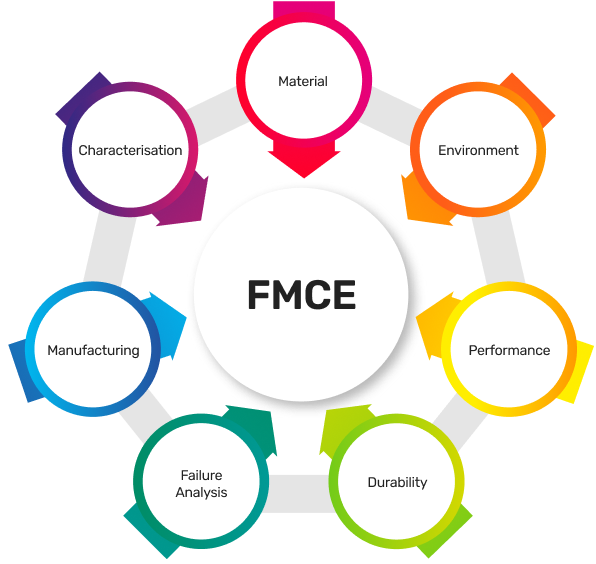

Fatigue and Materials Center of Excellence (FMCE) is one-stop shop for material engineering/science to full-vehicle validation

With state-of-the-art facilities for material characterisation, component-to-assembly validation and comprehensive solutions for vehicle level tests, FMCE is ready to provide Safe, Durable, and Economical & Environment- friendly solutions to the Industry. FMCE is also leading validation partner in other sectors such as railways, defence, construction machinery, elevator & infrastructure, medical equipment, packaging etc.

Majority of services provided by FMCE are under IS/ISO 17025:2020 accreditation

Our Expertise

Industries We Serve

Automotive

Automotive

Tractors & Farm Equipment

Tractors & Farm Equipment

Off-Road

Off-Road

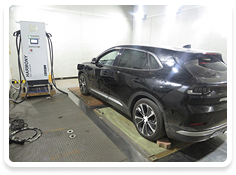

Electric Vehicle

Electric Vehicle

Technology

Technology

Energy

Energy

Gensets

Gensets

Aerospace

Aerospace

Railways

Railways

Defence

Defence

Elevators

Elevators

Medical

Medical

Shipping

Shipping

Construction

Construction

AT THE HEART OF WHAT WE DO

Our Core Services

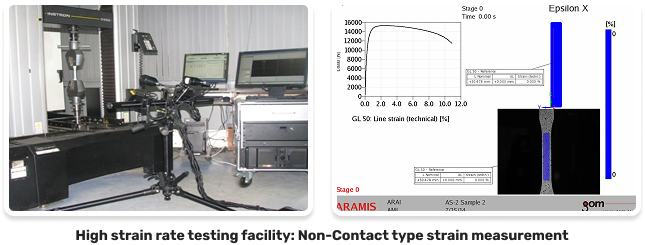

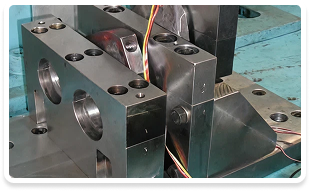

Mechanical Characterisation

- Metals, Plastics, Composites, Fabrics, Foams, Ceramics etc. Yield Strength, Ultimate Tensile Strength, % Elongation, Young’s Modulus, Poisson’s Ratio, Plastic Strain ratio (r-value), Tensile Strain hardening Exponent (n-value), Strength Coefficient (K), Compressive yield strength, Flexural strength / 3-Point bend test,

- At non-ambient temperature ranging -30°C to +250°C

- Push Test, Pull Test, Connector Force Test, Cyclic force V/s displacement

- Adhesives and sealants testing: Peel, Lap shear

- Coefficient of friction

- Stress V/s Strain data till failure

- Hardness

- Impact strength at room & subzero temperatures up to -40 Deg

- Creep testing (ASTM D2990, ISO 899)

- Load relaxation testing

- 2D/3D Digital Image Correlation for material coupons as well as components

- High strain rate tensile test

- Assessment of Materials behavior at high speed situations like crash.

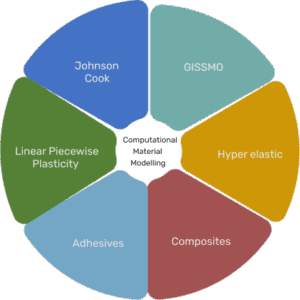

Computational Material Modelling

- Quantification of physical material properties, that is, the ability of your material to respond

- Material characterisation and generation of material model cards

- Strain Rate sensitive material models: MAT_024 (Linear Piecewise plasticity), MAT_015 (Johnson – Cook), MAT_024 with Cowper – Symonds, Damage Models: MAT_ADD_EROSION (GISSMO)

- Material Models for non-metallic materials (Elastomer & Adhesives): MAT_169,

Neo-Hookean, Mooney-Rivlin - Need of Material Modelling

- Eliminate trial and error in product design

- Prediction of material response & damage

- Consideration of physical influence in non-proportional loading

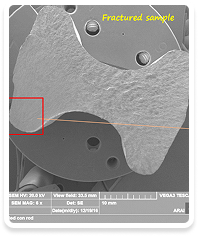

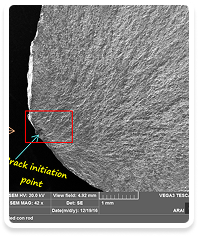

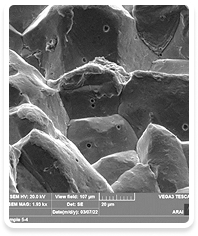

Metallurgical Characterisation, Process Development & Failure Analysis

- Failure Analysis

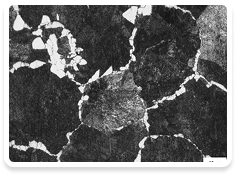

- Fractography, topography, morphology analysis

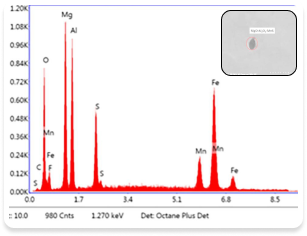

- Elemental analysis (Compositional, Mapping, Particles compositional analysis)

- Microstructure analysis (Inclusion, defects, phases, grain size, particle size analysis, weld analysis)

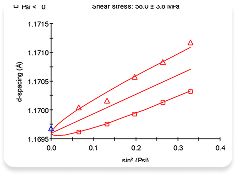

- Residual stress analysis for determination of stress fields w.r.t process variations, surface treatments, quality control

- Heat treatment (Coefficient of thermal expansion, CCT diagram)

Environmental Durability

- Plethora of facilities to test coupon samples up to vehicle level environmental tests

- Evaluation of Coatings and Paints

- Corrosion Evaluation

- Sunlight exposure test

- Extreme hot and cold weather testing

- Charging & battery performance at different temperatures

- Humidity and Heat-Ageing Tests

- Cold-startability & HVAC Performance

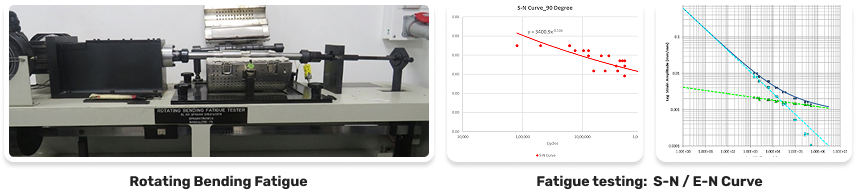

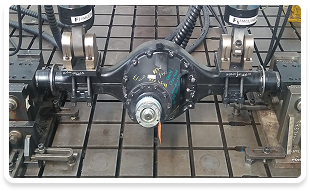

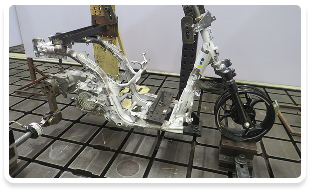

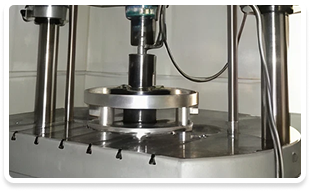

Component Validation

- Actuators with force ranges from 5-500kN and displacements up to 750 mm

- Static Strength Tests

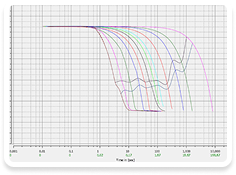

- Fatigue Testing

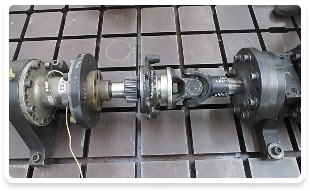

- Multi-axial Testing for Axles, Springs & Engine Mounts

- Performance Analysis : Stiffness measurements

- Battery & Cell-level Crush

- Battery Housing Burst and Leakage Tests

- Charger Performance Analysis

- Functional test on parts like seats, mirrors, latches etc.

Seating System Development

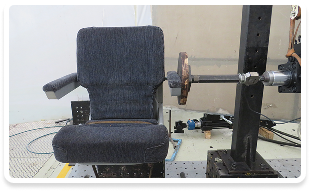

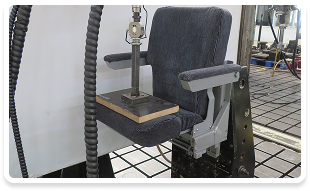

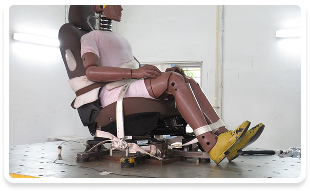

- Variety of Test rigs for complete Seat DVP Testing

- Static Strength Tests

- Functional Durability on Recliner, Track, Turntable, Arm Rest, etc.

- Multi-axial Vibration Testing as per OEM DVP

- Performance Tests: Cushion Damping, Torsional Stiffness

- Foam Durability

- Jounce Test

- Comfort Analysis on Human-Rated Test Rig – Subjective & Objective

- Railway Seat Tests as per UIC 566

- Berth Seat Testing

Service Data Acquisition (RLDA)

- Variety of Data Loggers to measure 100+ channels simultaneously with suite of sensors to measure

- Accelerations using DC & Piezo-Capacitive based Sensors

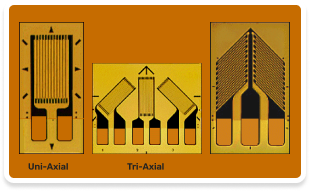

- Strain gauges for metals and non-metals

- Pressure Measurement for Hydraulic circuits and containers

- Dedicated Temperature Logger with Thermocouples, k-type sensors etc.

- Displacement sensors from 5 to 500 mm

- Mobile DAQ and sensor suite for on-site measurement

- Ride-Comfort Analysis as per ISO 2631

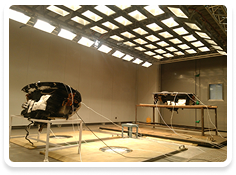

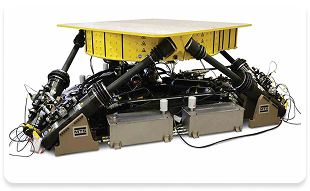

Vibration Testing

- Servo-Hydraulic Rig with slip table for uni-axial vibration tests

- High-Frequency Multi-axial rig

- 6 DOF MAST rig for Vibrational Durability with expandable option up to 8 DOF for Engine/Motor Mount and

- Cradle Durability

- ED Shaker with Slip Table for High Frequency Vibration Tests

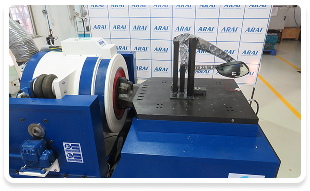

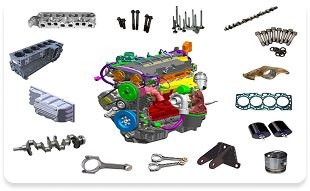

Engine Component Testing

- Comprehensive Test Solutions for validation of Engine components like Crankcase, Cylinder Head, Con-Rod, Cam Shafts etc.

- Servo-Hydraulic Rig for high-load con-rod testing

- High Frequency Pulsator machines for validation of con-rod, crankshaft etc.

- Torsion-Bending Rig using ED shaker

- Pressure Pulsation for Cylinder Head and Gasket validation

- Strain gauging and stress relief measurement activity with precision cutting apparatus

- Mobile Bolt pre-torque measurement apparatus for on-site measurement

- Residual Stress Analysis

FAST Lab (Infrastructure)

- Hydraulic Power Pack (HPS) of 2650 LMP, 210 Bar complete ring main

- Single & Multi-Channel Digital Controllers for Hydraulic and Pneumatic Test Rigs

- Universal Test Benches with linear actuator load capacities from 5 up to 500 kN

- Rotary Actuator up to 360° rotation and torque capacity up to 11 kNm

- Motor Controller with VFD Drive

- Data Loggers with 100+ channels synchronous logging

- Drive-in 4 Poster in Climatic Chamber

- Small Car Ambient 4 Poster Rig

- High Frequency Pulsator Machine of 250 kN & 600 kN capacity

- Climatic Chambers with Solar Simulation Capabilities

- DOF Multi-Axis Simulation Table with out-board fixtures for tests up to 9 DOF

- High-Freq MAST Rig up to 150 Hz and 1 ton payload

- Universal Test Machine (UTM) with provision for non-ambient testing (-30 to 180 °C)

- UV/Xenon Weathering

- Salt Spray Corrosion

- Residual Stress Analyser – XRD

- SEM and Optical Microscopes

- High-Strain Rate Machine with DIC