Automotive NVH

Services: Automotive NVH

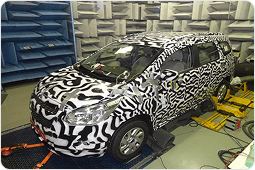

- Vehicle Interior Noise and Vibration Refinement

- NVH Benchmarking, DVP Development, Troubleshooting

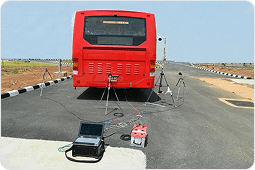

- Pass-by Noise Evaluation as per ECE R51, R41, IS 3028

- Pass-by Noise Source Identification and Reduction

- Transmission and Axle Whine Reduction

- Sound Quality Evaluation and Improvement

- AVAS Development for Electric Vehicles

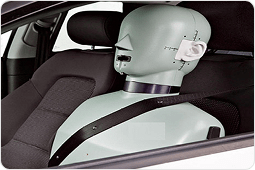

- Sound Signature Characterization by Head and Torso Simulator (HATS)

- Complete vehicle, sub-system and component level Transfer Path Analysis (TPA)

- Jury Evaluation for objective to subjective correlation

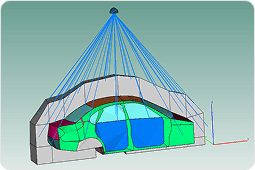

- Capability to address mid to high frequency NVH air borne sources using Hybrid and Pure SEA approach

- Vehicle Interior Simulation with acoustic trim optimization

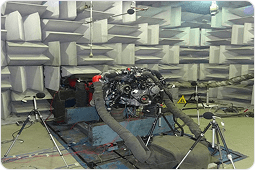

Powertrain NVH

- Leader in powertrain NVH development with 20+ years’ experience with engines ranging from 5 kW to 400 kW

- Engine calibration optimization

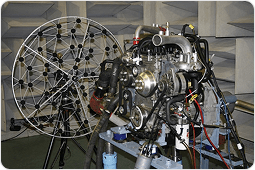

- Acoustic camera and sound intensity mapping

- Torsional vibration analysis

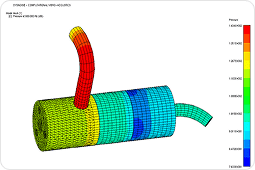

- Intake and Exhaust Design

Sound Package Development

- NABL Accredited facility

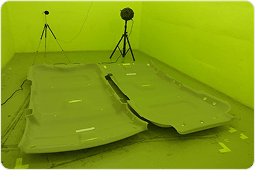

- Sound absorption testing and benchmarking of actual parts/components using Alpha Cabin.

- Sound Absorption Coefficient and Sound Transmission Loss of automotive as per ISO 354 / ASTM 423 / ISO 10140-2 / ASTM E 90 using reverberation chambers.

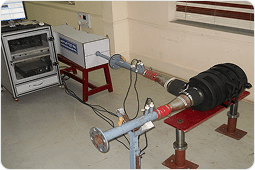

- Sound absorption coefficient as per ISO 10534 / ASTM 1050 / OEM’s using impedance tubes.

- BIOT’s parameter evaluation using specialised test rigs such as flow resistivity, porosity, mechanical analyser as per ASTM C 522.

- Acoustic performance evaluation of body cavity fillers and grommets as per SAE J2846.

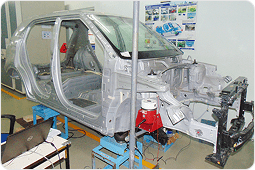

Modal Analysis

- Expertise to suggest improvement for structural and interior cavity optimization

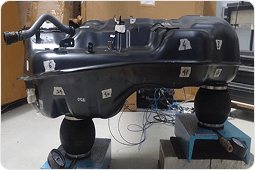

- Rigid Body Mode Evaluation

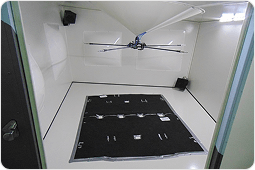

- Non-contact modal analysis, operational modal and deflection shapes analysis

- Global Torsional Stiffness for Comfort Statics Evaluation of BIW

- Rigid Body properties, Centre of Gravity and Moment of Inertia assessment for optimized vibration performance of engine at low frequencies

- Dynamic stiffness optimisation for BIW structures, Intake/exhaust hangers, tyres, etc.

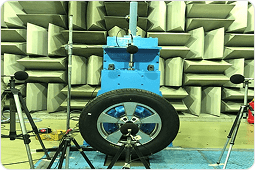

Tire Noise

- Tyre test rig with advanced capabilities to evaluate sound power level, close proximity and cavity noise evaluations for all passenger car tyre applications

- Tyre Cavity Noise Evaluation and Acoustic Material Characterization to reduce Cavity Resonance