NEW FACILITY

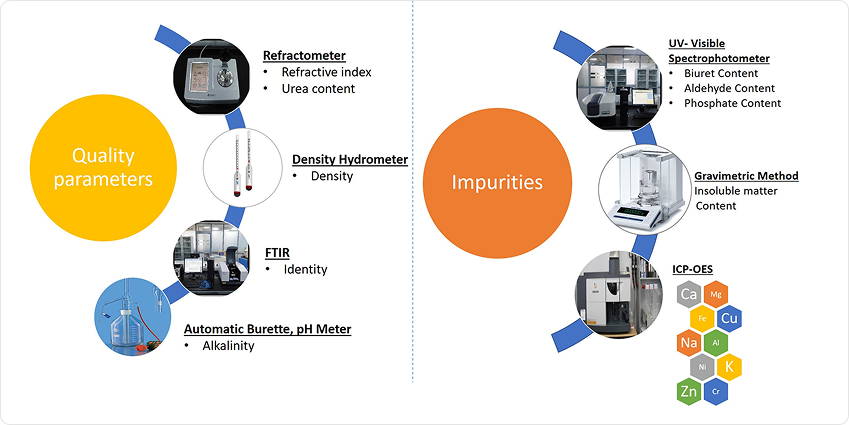

Evaluation of Diesel Exhaust Fluid (DEF) as per ISO 22241/IS 17042

Environment Research Laboratory (ERL) of ARAI has NABL accredited test facility for evaluation of Diesel Exhaust Fluid (DEF) as per ISO 22241/IS 17042. The laboratory houses state of the art of infrastructure, equipment and resources to deliver high quality DEF testing services. This expanded suite of testing services will assist automotive sector clients in meeting various national and international requirements. DEF is an aqueous Urea solution of 32.5% high purity Urea (A compound of Nitrogen that is converted to Ammonia when heated) and 67.5% deionized water. DEF is used in many modern diesel engine applications which uses Selective Catalytic Reduction (SCR) technology to convert the NOx into the harmless gases emitted by an exhaust system. Contaminants or impurities in the DEF can cause the breakdown of SCR system. Thus, it is important to maintain DEF quality standards.

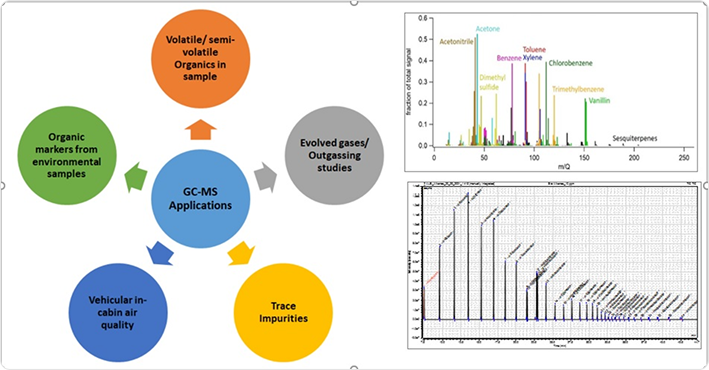

Testing and analysis of Molecular Markers and Volatile Organic Compounds (VOC) by Gas Chromatography – Mass Spectroscopy

A Gas Chromatograph – Mass Spectrometer (GCMS) facility for analysis of organic compounds is established at Environment Research Laboratory of ARAI. The facility is equipped with various accessories like head space and thermal desorption unit and can be utilised for analysis of organic compounds from samples in the form of liquid, solid, gaseous and particulate matter collected on filter paper. GCMS is an advance hyphenated analytical technique used for analysis of organic compounds in the sample. It has broad range of applications to cater to the requirements of sample analysis for presence of impurities, residual analysis, additives, volatile organic pollutants, etc. This versatile technique gives fast, reproducible and effective results and can be utilised for usage in various applications.

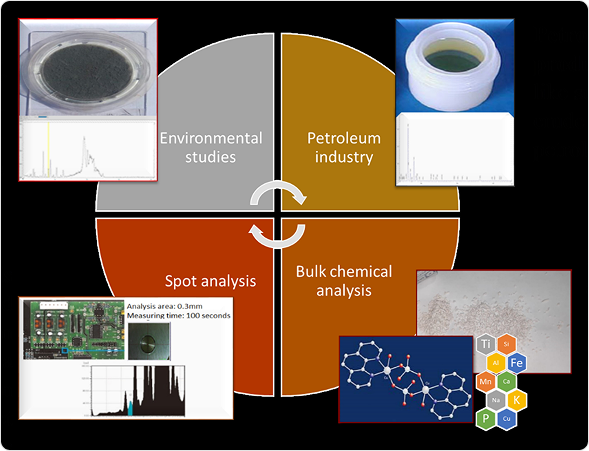

Screening for RoHS Substances with ED-XRF

Environment Research Laboratory (ERL) of ARAI is having test facility for Screening for RoHS Substances with Energy Dispersive X-ray Fluorescence (ED-XRF) spectrometer. ED-XRF testing is quick, with minimal sample preparation and non-destructive- meaning it can be performed at any point in the manufacturing process even on finished goods. ED-XRF can screen for RoHS i.e. Lead (Pb), Mercury (Hg), Cadmium (Cd), Chromium (Cr) and Bromine (Br) elements simultaneously in a variety of materials, all using one device. The maximum permitted concentrations are 0.1% or 1000 ppm (except for Cadmium, which is limited to 0.01% or 100 ppm) by weight of homogeneous materials.

Material Compatibility with Alternate Fuel

Material compatibility study is carried out on components at material level as per SAE J1747 and SAE J1748 on metal and non-metals( Plastics & Elastomers) respectively which are specific for assessment of impact of hydrocarbon fuels and their mixtures with oxygenated additives on metals and non-metals . The impact of alternate fuels, on the fuel system components of gasoline vehicles must be known for assessment of whether the fuel system will be able to perform as intended for the complete design life of the system. Material experts, design engineers can utilise this vital dataset to critically evaluate the same with due consideration to the significance of a property for intended application and service requirements of a components in which the materials are used.

- Physico-chemical properties and performance evaluation of automotive materials/components as per national/ international standards

-

- DOIhttps://doi.org/10.4271/2017-26-0072

- DOIhttps://doi.org/10.4271/2013-01-2880

- DOIhttps://doi.org/10.4271/2013-26-0077