SUB SECTION AT SHL

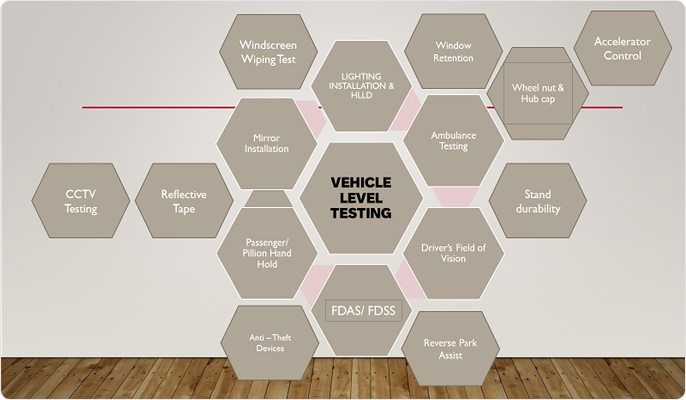

Vehicle Installation tests (CMVR Clearance)

Regulatory Compliance for Various Components After Installation as per CMVR

Other Services Offered Under Vehicle Installation Testing:

- Bus Body Testing and Clearance as per AIS:052 (Rev. 1) & AIS:153

- Construction Equipment Vehicle(s) Testing & Clearance as per AIS:160

- Installation Level Testing

- Whole Vehicle COP (WVSCoP) as per AIS-017 (Part 6) & its Amendments

- Ambulance Testing and Clearance

- Agricultural Tractors Testing and Clearance

- Trailer Testing and Clearance as per AIS:113 & its Amendments

- Mining Vehicle Testing (Developmental Testing)

Centre of Excellence for Tyres and Wheel Rims

Facility Highlights

- Tyre Rolling Resistance Facility – Highly accurate state-of-the-art temperature-controlled Tyre Rolling Resistance (RR) test machine which can measure RR up to 15 N/kN. Machine can test tyre up to max load of 8000 kg and max speed 200 km/h with adjustable initial slip and camber angles for tyre development.

- 2-4 Stations Tyre Load Speed Performance Test Facility

- High Load Radial Fatigue Test – Can sustain load till 150 kN & max speed of 150 km/h

- Torsional Moment Test (Torsional Durability Test) – Used to ensure that the wheel can sustain the fatigue offered by sticky tires, high horsepower engines, and fast stopping brakes with max load ±2500 N

- Cornering Fatigue Test (CFT) offering bending moment up to 2 kNm, 5 kNm, and 30 kNm

- Plunger & Bead Unseating Facility

- Benchmarking – Influence of tyre on fuel consumption

Present Regulatory requirements for tyres in India

IS: 15633: 2005:

For Automotive Vehicles Pneumatic Tyres For Passenger Car Vehicles – Diagonal And Radial Ply

IS: 15636: 2012:

For Automotive Vehicles Pneumatic Tyres For Passenger Car Vehicles – Diagonal And Radial Ply

- Marking and Dimensions

- Load / Speed performance test

- Endurance test

- Tyre strength test (Plunger test)

- Dynamic Growth Test for diagonal & Bias tyres

IS 15627: 2005:

For Automotive Vehicles Pneumatic Tyres For Passenger Car Vehicles – Diagonal And Radial Ply

IS: 15633: 2005:

For Automotive Vehicles Pneumatic Tyres For Passenger Car Vehicles – Diagonal And Radial Ply

- Marking and Dimensions

- Load / Speed performance test

- Endurance test

- Bead unseating- Not applicable for IS:15636)

- Tyre strength test (Plunger test)

AIS-110: 2009:

For Automotive Vehicles Pneumatic Tyres For Passenger Car Vehicles – Diagonal And Radial Ply

IS: 15633: 2005:

For Automotive Vehicles Pneumatic Tyres For Passenger Car Vehicles – Diagonal And Radial Ply

- Marking and Dimensions

- Load / Speed performance test

- Endurance test

- Bead unseating- Not applicable for IS:15636)

- Tyre strength test (Plunger test)

AIS:142:

Pneumatic Tyres For four wheeled motor vehicles

- Tyre Rolling Resistance Test

- Adhesion on wet surfaces (Wet Grip)

- Tyre Rolling Sound Emissiontest

- Measurement

Advanced Photometry and Optics Laboratory (HTC- Chakan)

- ISO:17025 (NABL) accredited State of the art facility providing one stop solution for all testing, development & certification requirements of Automotive Lighting & General Lighting according to National & International standards such as AIS, ECE, EEC, ADRs, SANs, IEC, IS etc

- Preferred laboratory for export homologation testing by TUV, IDIADA, VCA, Bureau Veritas etc

- Collaboration with international ISO / IEC 17025 accredited labs such as TUV -Germany, Dekra – Netherlands, LTIK – Germany, and FAKT – Italy for Indian homologation services

- The preferred choice for Inter-lab comparison by other test labs and component manufacturers

Facility Highlights

- Life Test Rig for durability / endurance testing of general lighting components

- Type C Goniometer offering evaluation of all types of indoor and outdoor lights, streetlights, flood lights, portable luminaires etc. as per various National & International standards (various IS, LM and IEC standards)

- 1 m & 2 m Integrating Sphere for evaluation of light sources & measurements required in case of design and development, production and quality control of various types of LEDs, OLEDs and luminaires

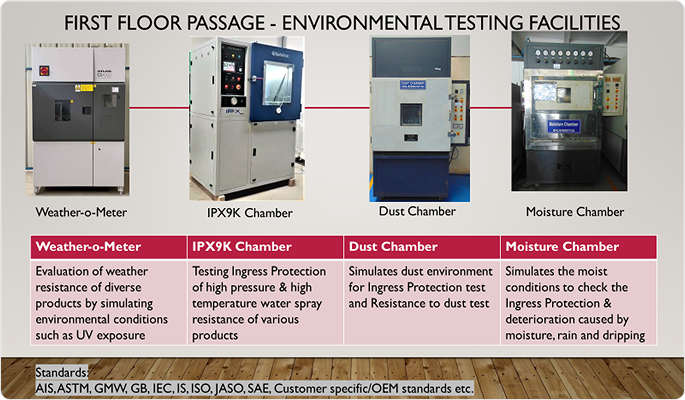

- Weather-o-meter for evaluation of weather resistance of diverse products by simulating environmental conditions such as UV exposure

- Electrical Safety Test Facilities such as ball pressure test apparatus, PAAC/PAES test equipment, spring operated impact test equipment, standard (jointed) test finger (test probe B), bending test equipment, digital torsion test equipment, digital axial test equipment, cord anchorage pull force & torque test equipment etc.

- Surface Colorimeter (Spectrophotometer) measures the light reflected at all angles to calculate a color measurement that closely matches human vision

Cylinder Testing Facility (MRC Takve)

First of its kind in the country to be used by PESO and cylinder manufacturers for testing and certification of various types of gaseous cylinders (Type 1, 2, 3, 4 cylinders), enabling testing of products indigenously and supporting manufacturers under the Startup, MSMEs scheme and Auto PLI scheme as a part of supporting the Aatmanirbhar Bharat mission. This facility will support the following activities:

- Type approval testing (Prototype approval / New design approval)

- Batch testing (In-production check)

- Periodic certification of gaseous cylinders (Cascades / In-use cylinders)

- Promote pure hydrogen-fueled vehicles.

Facility for testing & certification of Mirrors, Safety Glass, Hinges & Latches, Camera monitoring System etc

- State-of-the-art facility for testing of raw glasses and finished safety glasses (Automotive / Non-Automotive) for validation and certification as per Indian and International standards is established in the Safety and Homologation Lab (SHL), ARAI

- These facilities are recognized labs for BIS under LRS Scheme for IS 2553 (Part 1)-2018 and IS 2553 (Part 2)-2019 and ISO 17025-2017 (NABL) accredited.

- Helmed with a camera monitoring system facility for image quality evaluation, field of view (FoV) & coverage testing, latency & real-time system performance, display readability & HMI ergonomics, environmental & durability testing, fail-safe & diagnostic functionality as per AIS 001, ISO 16505 and ECE R46.

- The lab also features facilities for testing & certification of traditional rear-view mirrors (IRVM & ORVM).

Facility for testing & Certification of Brake Hoses, CNG, LPG, HCNG, LNG, Horns, Speed Limiting devices, plastic & metallic Fuel tanks etc

SHL offers multiple facilities for testing of active safety components such as brake hoses, brake fuild, CNG, LPG, HCNG, LNG cylinders, Speed Limiting Devices, Washer Tank, Wiper blades, Plastic & Metallic Fuel Tank. SHL also offers Fire test for batteries and Fuel tanks.

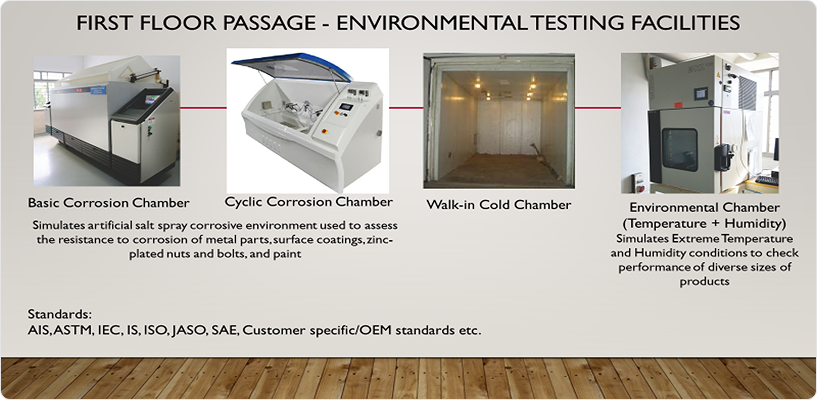

Environmental Testing Facilities

SHL offers a plethora of facilities that can be utilized for developmental tests such as IP series tests, environmental & weathering tests; solar simulation, ozone exposure, salt spray, Endurance tests, Imapct test, and many more.