ICME

ICME

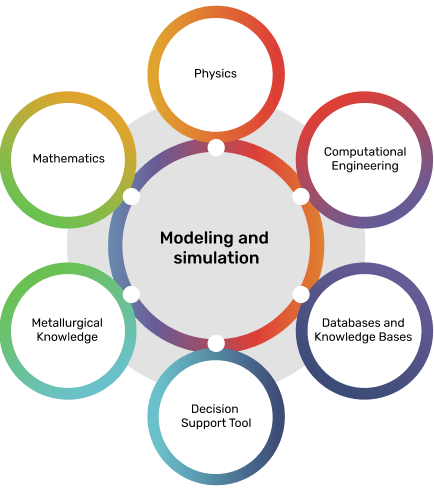

- Metal, Non Metal, Composite Modeling including Atomistic Calculations, Density Function Theory, Phase Field Modeling, Dislocation Dynamics to Macro Scale

- Accessible to multiple users with Server GPU/CPU located @ Hub accessible to Spoke1 and Spoke2

- 48 GB Computation power

- 56 * 2 cores processing powe

- Expandable infrastructure

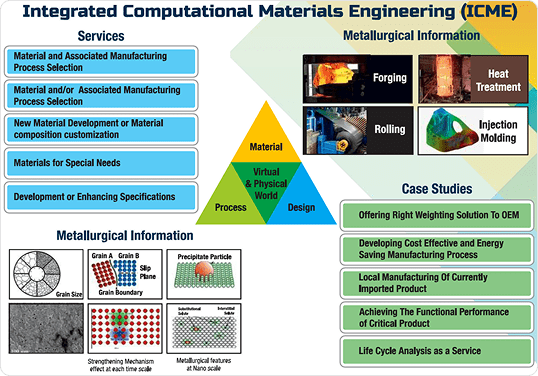

What is ICME?

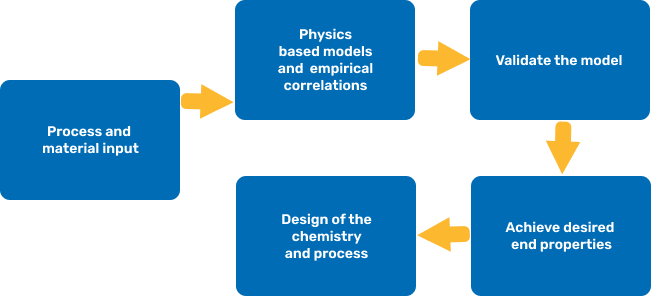

- An approach to design products and the materials that comprise them and capturing the anisotropy

- A way to increase computational capabilities to mimic/replicate the real processes in virtual world

- ICME acts as a function of local properties of the material inside a component and the characteristics of the manufacturing process

- An integration of material models and Process Structure Property relationships across time and length scale

ICME Framework

ARAI ICME Centre @Pune, Bengaluru & Guwahati

For software providers

- SaaS (Software as a Service

- Calculation on demand

- Increased use of personalized software codes will benefit for the 2nd simulation

For industrial users

- Reducing design efforts

- Product & process improvement

- Reduction in manufacturing costs

Of the Platform concept

- Open architecture

- Easy access

- Self amplifications of data and simulation codes